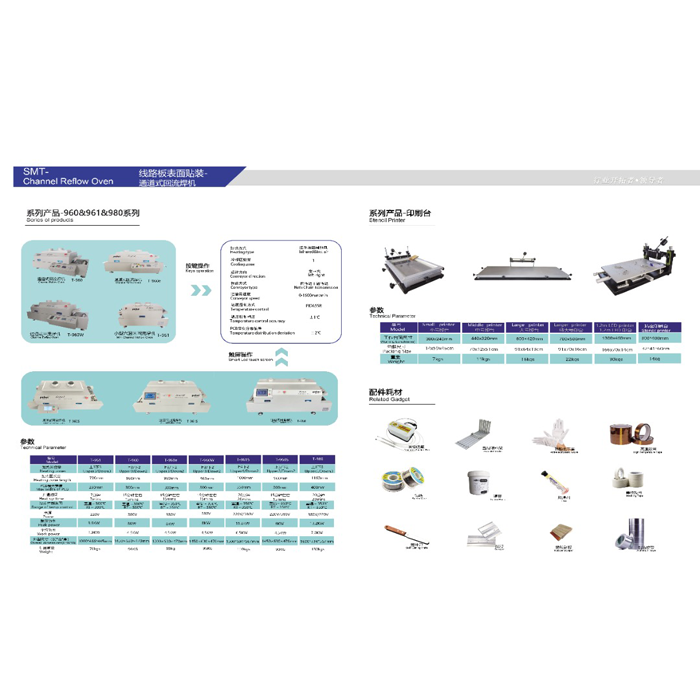

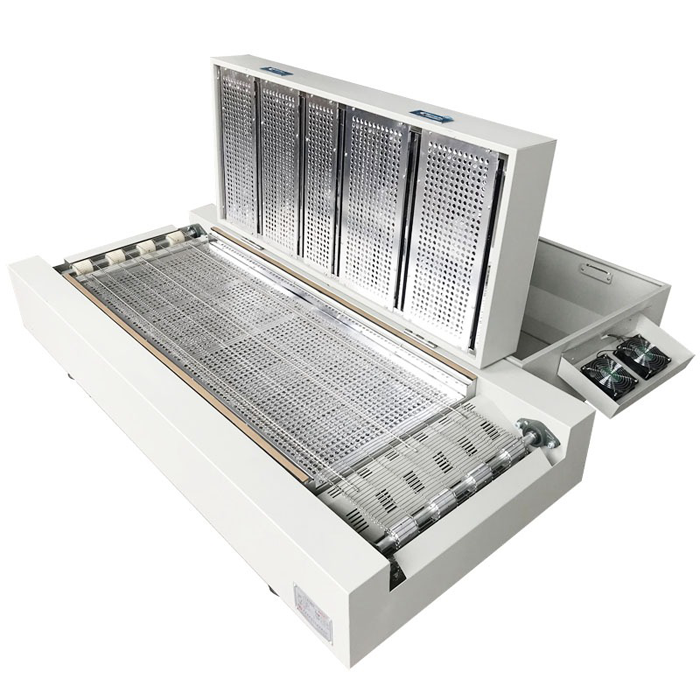

T-980

The T-980 is a smart touch screen PCB welding machine designed for efficient and precise soldering in modern electronics manufacturing. It features eight heating zones, utilizing a combination of infrared and hot air heating technologies to ensure uniform temperature distribution and high-quality results. The conveyor system provides smooth and consistent PCB transport, while the advanced PID closed-loop temperature control ensures accuracy and stability. With a spacious soldering area of 400 × 1160 mm, it accommodates various PCB sizes and components, including LEDs and ICs. Compact, reliable, and user-friendly, the T-980 is ideal for small to medium-scale production and prototyping.