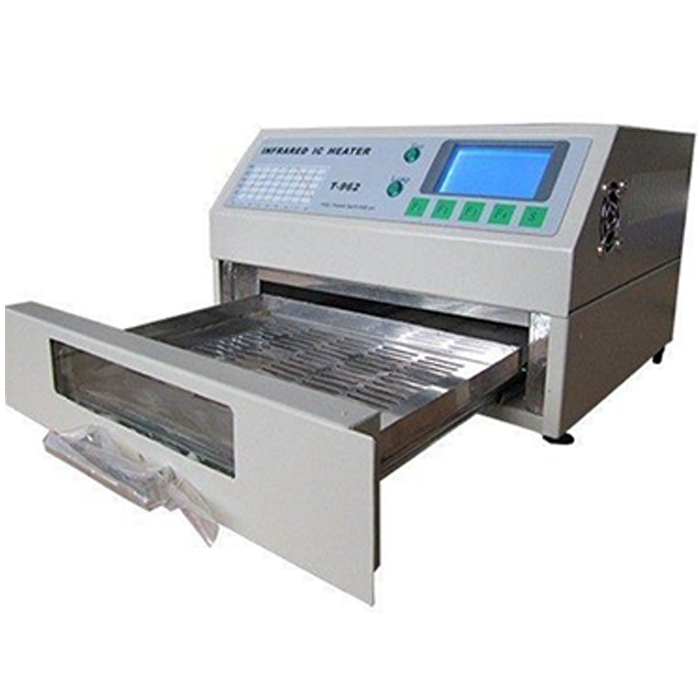

T-962

The T-962 is a compact and efficient infrared reflow oven designed for soldering various SMD and BGA components. It features a user-friendly interface and automated soldering processes, ensuring consistent and high-quality results. With its precise temperature control and even heat distribution, it is suitable for small-scale production, prototyping, and rework tasks. Its ergonomic design and versatility make it a reliable choice for modern electronic manufacturing needs.